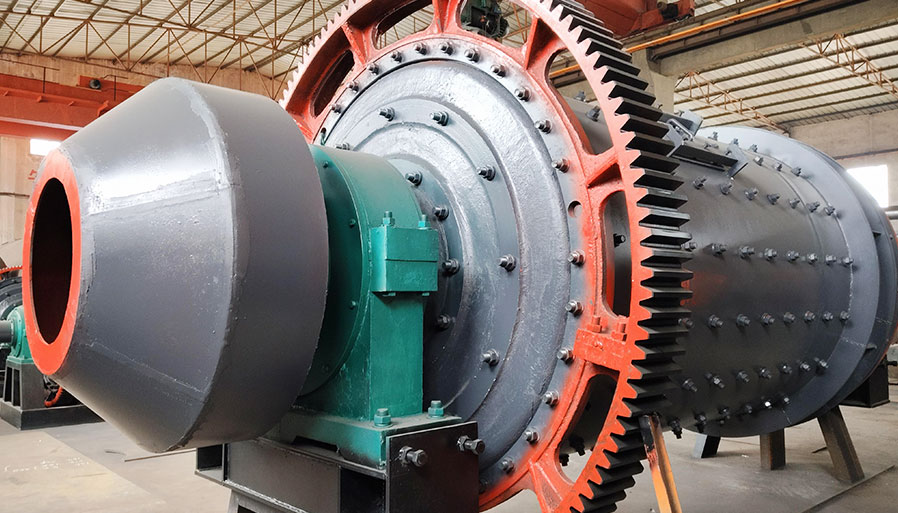

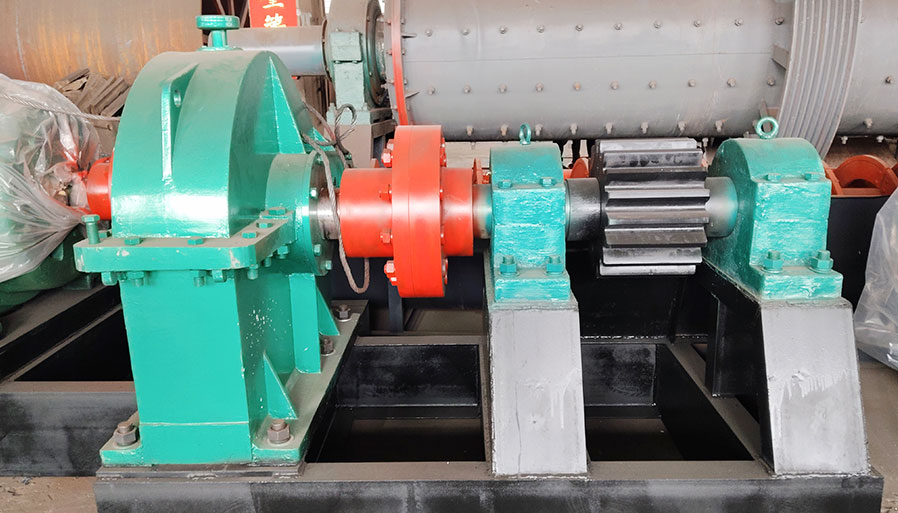

The ball mill is a key equipment for crushing materials after they are broken. This type of grinding mill is to load a certain number of steel balls into its cylinder as grinding media. When the cylinder of the ball mill rotates, the grinding bodies are attached to the cylinder lining due to inertia, centrifugal force, and friction, and are carried away by the cylinder. When they are brought to a certain height, they are thrown down due to their own gravity. The falling grinding bodies crush the materials in the cylinder like projectiles.

Widely used in cement, silicate products, new building materials, refractory materials, fertilizers, non-ferrous metal beneficiation, glass ceramic building materials and chemical industries.

|

Model |

Rotary Speed (r/min) |

Ball Weight (t) |

Feeding |

Output Size |

Capacity |

Motor power (kw) |

Weight (t) |

|

Φ900x3000 |

35.6 |

2.4 |

≤25 |

0.075~0.89 |

0.8-2.5 |

22 |

5.3 |

|

Φ1200x3000 |

32.4 |

4.5 |

≤25 |

0.074~0.4 |

1.6-3 |

37 |

12.1 |

|

Φ1200x4500 |

32.4 |

7 |

≤25 |

0.074~0.4 |

1.83-3.9 |

55 |

13.1 |

|

Φ1500x3000 |

29.7 |

7.5 |

≤25 |

0.074~0.4 |

2.8-4 |

75 |

14.8 |

|

Φ1500x4500 |

29.7 |

11 |

≤25 |

0.074~0.4 |

4.8-7 |

110 |

19.9 |

|

Φ1500x5700 |

29.7 |

14 |

≤25 |

0.074~0.4 |

5-8 |

130 |

23.4 |

|

Φ1500x7000 |

29.7 |

17 |

≤25 |

0.074~0.4 |

6-8 |

155 |

27.5 |

|

Φ1830x3000 |

25.4 |

11 |

≤25 |

0.074~0.4 |

4.5-10.5 |

130 |

26.6 |

|

Φ1830x4500 |

25.4 |

17 |

≤25 |

0.074~0.4 |

6.8-11.5 |

155 |

30.4 |

|

Φ1830x6400 |

25.4 |

24 |

≤25 |

0.074~0.4 |

7-12 |

210 |

32.3 |

|

Φ1830x7000 |

25.4 |

26 |

≤25 |

0.074~0.4 |

7.8-13.8 |

245 |

34.2 |

|

Φ2100x3000 |

24.9 |

15 |

≤25 |

0.074~0.4 |

5.8-14 |

210 |

32.3 |

|

Φ2100x4500 |

24.9 |

23 |

≤25 |

0.074~0.4 |

9.5-18 |

245 |

40 |

|

Φ2400x3000 |

20.8 |

20 |

≤25 |

0.074~0.4 |

7.8-18 |

245 |

51.3 |

|

Φ2400x4500 |

20.8 |

30 |

≤25 |

0.074~0.4 |

13.7-28 |

380 |

63.7 |

|

Φ2700x4000 |

19.5 |

34 |

≤25 |

0.074~0.4 |

15-28 |

475 |

89 |

|

Φ2700x4500 |

19.5 |

39 |

≤25 |

0.074~0.4 |

16.5-36 |

475 |

97 |

Ball mills are suitable for various types of materials, whether it is ore, slag, cement clinker or chemical raw materials, they can be ground.

Ball mills have a large crushing ratio and high production capacity, which can meet the needs of large-scale production.

It can be operated dry or wet, and drying and grinding can be combined.

The ball mill has a simple structure, reliable operation, simple maintenance and management, and can operate continuously for a long time.

Although the efficiency of the ball mill is relatively low, its energy consumption is low and it is suitable for long-term operation.

We configured a PE500X750 and PYB900 cone crusher combined mobile station for the customer. The vibrating feeder feeds the granite below 400mm into the PE500x750 jaw crusher for primary crushing, and then it to the PYB900 cone crusher for secondary crushing. The vibrating screen is used to screen out the finished building materials required by the customer.

We configured a PE500X750 and PYB900 cone crusher combined mobile station for the customer. The vibrating feeder feeds the granite below 400mm into the PE500x750 jaw crusher for primary crushing, and then it to the PYB900 cone crusher for secondary crushing. The vibrating screen is used to screen out the finished building materials required by the customer.

The customer required to produce powder below 1mm, and the output is 30-50 T/H, so we configure a fine crusher as the secondary crusher for the customer.

Fill in the information and we will contact you as soon as possible