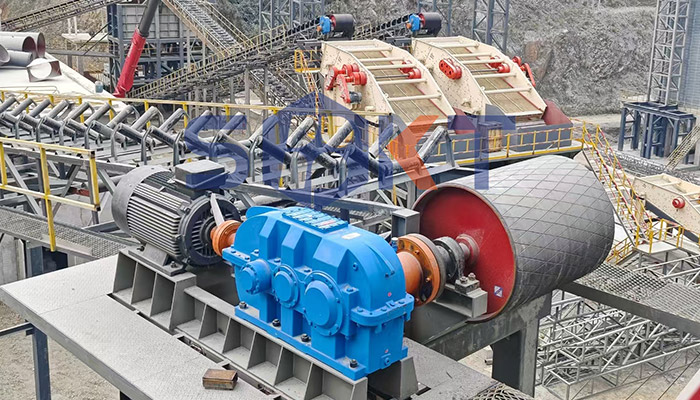

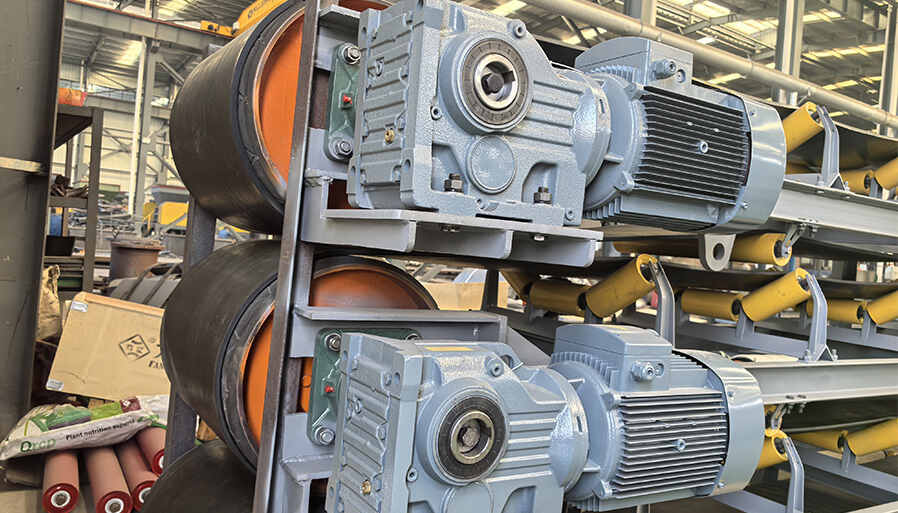

This machine is used for transferring bulk or packaged materials, it is widely used in the industry of mining, building materials, metallurgy, coal and so on, According to various transferring requirements, the transferring system can be single or multiple conveyors or combined with other equipment to make up slope or horizontal transfer system to meet the need of different working conditions, The machine has advantages of large transfer quantity, simple operation,convenient maintenance and standard parts of the conveyor.

Mining

Metallic minerals

Recycled Aggregates

Architecture

|

Belt Width |

Belt Length(m)/Powerm(kW) |

Belt Speed(m/s) |

Capacity(t/h) |

||

|

500 |

≤12/4 |

12-20/5.5 |

20-30/7.5 |

1.3-1.6 |

60-156 |

|

650 |

≤12/4 |

12-20/5.5 |

20-30/7.5 |

1.3-1.6 |

110-264 |

|

800 |

10-15/7.5 |

15-20/11 |

20-30/15-18.5 |

1.3-1.6 |

184-445 |

|

1000 |

10-15/11 |

15-23/15 |

23-32/22 |

1.3-2.0 |

288-696 |

|

1200 |

10-18/15 |

18-22/18.5 |

22-30/22-30 |

1.3-2.0 |

432-1048 |

|

1400 |

10-18/22 |

18-22/30 |

22-30/30-37 |

1.3-2.0 |

588-1427 |

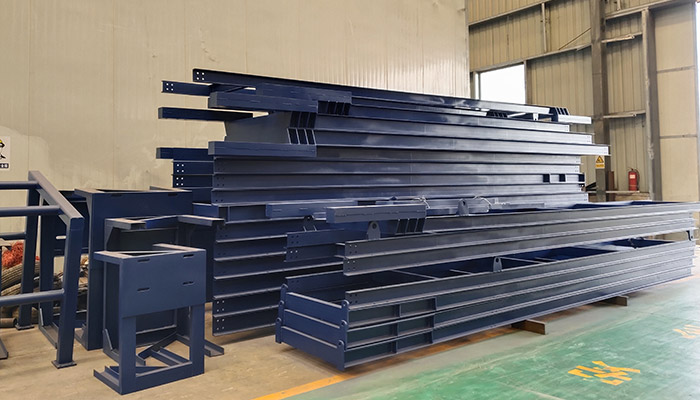

The belt conveyor series produced by our company has the advantages of large conveying capacity, simple structure, easy maintenance, and standardized components.

According to the requirements of the conveying process, it can be conveyed by a single machine, or composed of multiple machines or other conveying equipment.

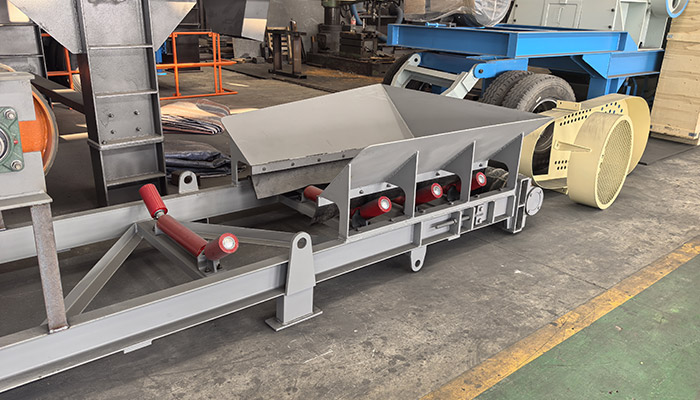

We configured a PE500X750 and PYB900 cone crusher combined mobile station for the customer. The vibrating feeder feeds the granite below 400mm into the PE500x750 jaw crusher for primary crushing, and then it to the PYB900 cone crusher for secondary crushing. The vibrating screen is used to screen out the finished building materials required by the customer.

We configured a PE500X750 and PYB900 cone crusher combined mobile station for the customer. The vibrating feeder feeds the granite below 400mm into the PE500x750 jaw crusher for primary crushing, and then it to the PYB900 cone crusher for secondary crushing. The vibrating screen is used to screen out the finished building materials required by the customer.

The customer required to produce powder below 1mm, and the output is 30-50 T/H, so we configure a fine crusher as the secondary crusher for the customer.

Fill in the information and we will contact you as soon as possible