Crawler mobile crushing station is a kind of efficient crushing equipment. It adopts hydraulic and other non-powerful methods to drive and control crawler movement, equipment installation and operation. It has higher energy utilization efficiency and can reach any location of the work site in any terrain. It has higher production efficiency and creates greater value for users.

Crawler mobile crushers are widely used in mining, construction, environmental protection and other fields due to their strong mobility, adaptability to complex terrain, and rapid transfer.

CRAWLER TYPE MOBILE JAW CRUSHER PLANT

|

Model |

LA-116 |

LA-106 |

LA-96 |

|

Feeder bucket capacity(m³) |

6m³ |

5m³ |

5m³ |

|

Max.Feeding size(mm) |

1100X850 |

1060X700 |

960x580 |

|

The engine power(kw) |

196.2 |

141.4 |

112.9 |

CRAWLER TYPE MOBILE Heavy Hammer CRUSHER PLANT

|

Model |

LA-1615 |

LA-1512 |

LA-1308 |

|

Feeder bucket capacity(m³) |

6m³ |

5m³ |

5m³ |

|

Max.Feeding size(mm) |

750 |

700 |

600 |

|

The engine power(kw) |

350-3800 |

300-350 |

162-200 |

CRAWLER TYPE MOBILE IMPACT CRUSHING PLANT

|

Model |

LA-150 |

LA-250 |

LA-350 |

|

Feeder bucket capacity(m³) |

3m³ |

5m³ |

5m³ |

|

Max.Feeding size(mm) |

980X820 |

960X1360 |

1050X1700 |

|

The engine power(kw) |

253 |

304 |

366 |

CRAWLER TYPE MOBILE CONE CRUSHING PLANT

|

Model |

LA-CP300 |

LA-CP400 |

LA-830 |

LA-840 |

|

Feeder bucket capacity(m³) |

3m³ |

3m³ |

3m³ |

3m³ |

|

Max.Feeding size(mm) |

185 |

210 |

190 |

215 |

|

The engine power(kw) |

267-300 |

365-420 |

267-300 |

365-420 |

CRAWLER TYPE MOBILE SCREENING PLANT

|

Model |

LA-1860 |

LA-2160 |

|

Max.Feeding size(mm) |

300 |

300 |

|

The engine power(kw) |

37.5 |

65.5 |

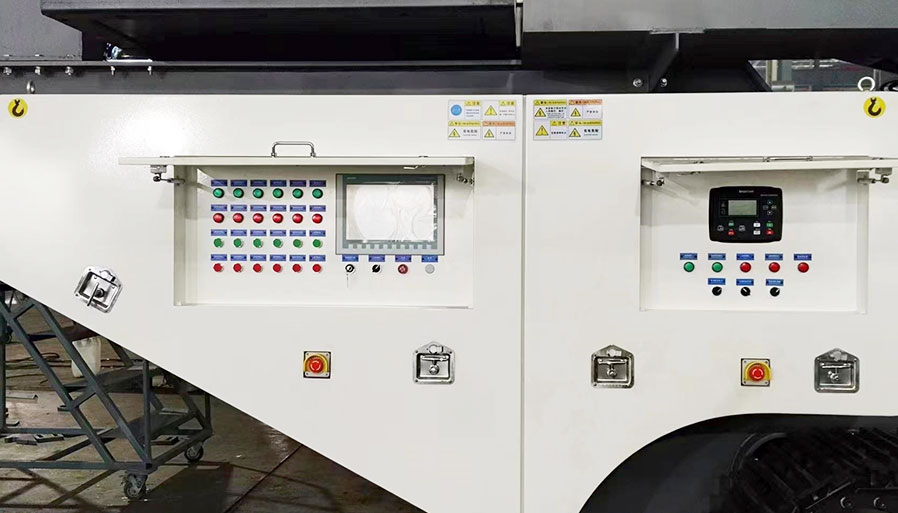

Stable and Reliable More Effective .

Hydraulic Control Stability and Energy Saving.

Strong Power Flexible performance.

Flexible Configuration Wide Application.

We configured a PE500X750 and PYB900 cone crusher combined mobile station for the customer. The vibrating feeder feeds the granite below 400mm into the PE500x750 jaw crusher for primary crushing, and then it to the PYB900 cone crusher for secondary crushing. The vibrating screen is used to screen out the finished building materials required by the customer.

We configured a PE500X750 and PYB900 cone crusher combined mobile station for the customer. The vibrating feeder feeds the granite below 400mm into the PE500x750 jaw crusher for primary crushing, and then it to the PYB900 cone crusher for secondary crushing. The vibrating screen is used to screen out the finished building materials required by the customer.

The production line is reasonably designed and has strong processing capacity, which is suitable for large-scale granite crushing operations. The equipment is highly efficient, has a large crushing ratio, and the finished product has a uniform particle size, which can meet high-standard production needs.

Fill in the information and we will contact you as soon as possible