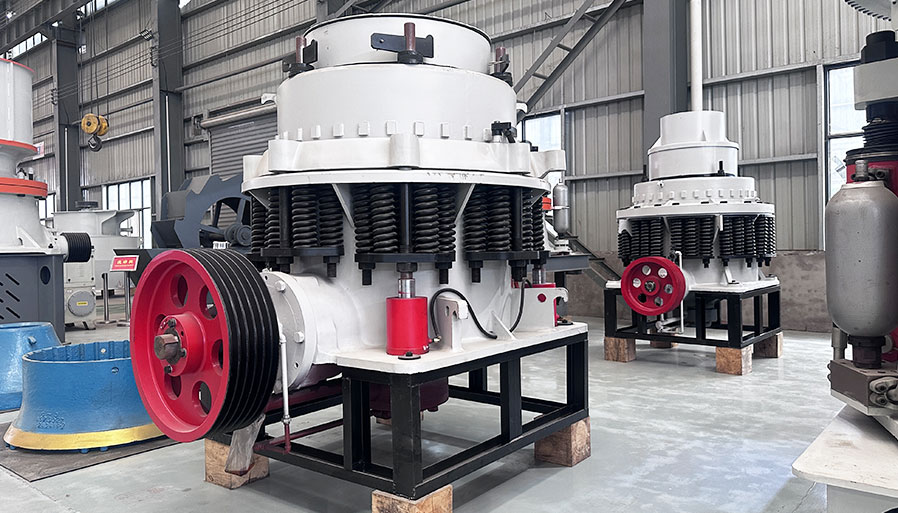

PSG series Simmons cone crusher is suitable for crushing ores and rocks with medium hardness or above.

It is widely used in metallurgical industry, construction materials industry, road building industry, chemical industry and silicate industry.

| Technical Specification | ||||||||||||||

| Model | Cavity Type |

Max Feeding Size(mm) | Min.Discharging Port size (mm) | Motor Power(kW) | Closed Edge Material-discharging Port(mm) Output(TPH) | |||||||||

| 6 | 10 | 13 | 16 | 19 | 22 | 25 | 38 | 51 | 64 | |||||

| CSV60 | C | 95 | 10 | 45 | 20 | 53 | 30 | 35 | 45 | 50 | 75 | |||

| M | 72 | 6 | 18 | 20 | 25 | 30 | 35 | 40 | 45 | 60 | ||||

| CSV110 | C | 160 | 13 | 110 | 80 | 100 | 135 | 150 | 175 | 235 | ||||

| M | 115 | 10 | 65 | 75 | 90 | 120 | 135 | 150 | ||||||

| F | 80 | 8 | 50 | 55 | 65 | 70 | 95 | |||||||

| EF | 50 | 6 | 52 | 62 | 72 | 78 | 102 | |||||||

| CSV132 | C | 180 | 13 | 132 | 115 | 135 | 150 | 180 | 200 | 260 | ||||

| M | 130 | 10 | 100 | 110 | 120 | 135 | 165 | 175 | ||||||

| F | 90 | 10 | 80 | 105 | 110 | 140 | ||||||||

| EF | 60 | 6 | 60 | 74 | 105 | 110 | 130 | |||||||

| CSV160 | C | 200 | 16 | 160 | 150 | 180 | 200 | 230 | 310 | 390 | ||||

| M | 150 | 13 | 115 | 140 | 160 | 190 | 210 | |||||||

| F | 102 | 10 | 90 | 115 | 145 | 160 | ||||||||

| EF | 70 | 8 | 88 | 110 | 135 | 155 | ||||||||

| CSV200 | C | 215 | 19 | 200 | 200 | 220 | 260 | 330 | 420 | |||||

| M | 160 | 16 | 155 | 180 | 200 | 220 | ||||||||

| F | 115 | 13 | 150 | 190 | 210 | 230 | ||||||||

| EF | 76 | 8 | 122 | 148 | 185 | 200 | ||||||||

| CSV250 | C | 235 | 22 | 250 | 240 | 265 | 300 | 400 | 510 | 570 | ||||

| M | 175 | 19 | 215 | 240 | 265 | 320 | ||||||||

| F | 130 | 13 | 180 | 210 | 235 | 255 | 275 | |||||||

| EF | 90 | 10 | 148 | 178 | 220 | 265 | ||||||||

| CSV315 | C | 360 | 22 | 315 | 330 | 390 | 525 | 655 | 725 | |||||

| M | 203 | 16 | 230 | 270 | 300 | 330 | ||||||||

| F | 140 | 13 | 185 | 225 | 265 | 340 | ||||||||

| EF | 95 | 10 | 180 | 220 | 260 | 335 | ||||||||

Strong crushing force, reliable structure, high efficiency, high output, low operating cost, convenient adjustment, economical and affordable.

Medium and large cone crushers adopt multi-cylinder hydraulic locking and clearing system, which can reduce downtime and save workers' labor intensity.

PSG series also adopts hydraulic locking and mechanical locking, which is more reliable.

Each model has a variety of cavity types, and customers can choose different cavity types according to different requirements.

The use of compensating grease seal can prevent the lubricating oil from being contaminated by dust, so that each component can work reliably and have a long service life.

The safety insurance system adopts a spring group to make foreign matter and iron ore fall from the crushing cavity without damaging the crusher, which is simple and reliable.

We configured a PE500X750 and PYB900 cone crusher combined mobile station for the customer. The vibrating feeder feeds the granite below 400mm into the PE500x750 jaw crusher for primary crushing, and then it to the PYB900 cone crusher for secondary crushing. The vibrating screen is used to screen out the finished building materials required by the customer.

The customer required to produce powder below 1mm, and the output is 30-50 T/H, so we configure a fine crusher as the secondary crusher for the customer.

The production line is reasonably designed and has strong processing capacity, which is suitable for large-scale granite crushing operations. The equipment is highly efficient, has a large crushing ratio, and the finished product has a uniform particle size, which can meet high-standard production needs.

Fill in the information and we will contact you as soon as possible