A complete analysis of the crushing and sand making process: the key links from coarse crushing to fine crushing/Shengbang Machinery: one-stop crushing equipment and services

Ⅰ. Primary crushing: the core choice of primary crushing equipment

The primary crushing process usually uses a jaw crusher or a gyratory crusher. As a traditional primary crushing equipment, the jaw crusher has a stable structure and is widely used, suitable for all kinds of scale selection sites; the gyratory crusher performs outstandingly in large mines, has strong processing capacity, can cope with high production needs, and lays the foundation for subsequent processing.

Ⅱ. Secondary crushing: the balance between efficiency and cost of secondary crushing equipment

Secondary crushing equipment mainly includes impact crusher, fine jaw crusher and cone crusher. Fine jaw crusher has low investment and simple maintenance, which is suitable for small-scale selection, but the discharge particle size is larger; cone crusher has complex structure and high cost, but it can provide finer particle size and longer wear-resistant parts life. It can effectively reduce the overall cost when used in large-scale selection, and is the preferred choice for pursuing efficient production.

III. Fine crushing and screening: a key step to improve dry selection rate

The crushed materials are screened by a circular vibrating screen. The materials below 10mm are directly dry selected, 10-40mm are finely crushed, and the materials above 40mm are returned for re-crushing. There are various fine crushing equipment. Hammer crushing has low cost but poor efficiency. High-efficiency fine crushers, vertical shaft impact crushers and other equipment can significantly improve fine crushing efficiency and reduce resource waste. They are an important part of optimizing the crushing process.

Shengbang Machinery: One-stop crushing equipment and services

Ⅰ. Full-process equipment configuration plan

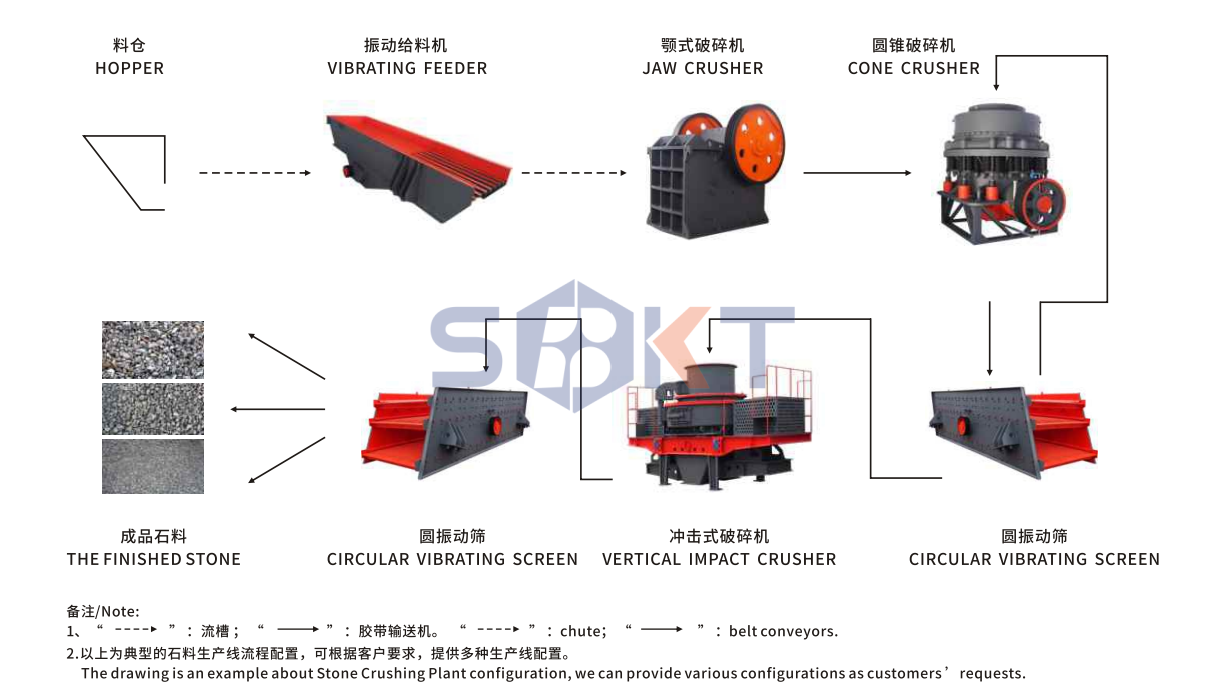

Provide the golden combination of “jaw crusher (primary crushing) + cone crusher (secondary crushing) + vertical shaft impact crusher (fine crushing) + intelligent screening system”, support customized design, and create exclusive crushing process according to different selection scales and ore characteristics to maximize production capacity.

Ⅱ. Core technical advantages

It has dual-rotor two-stage crushing technology, with large output and fine material output, and the proportion of materials below 3mm can reach 90%; the centralized lubrication system supports non-stop lubrication and convenient maintenance; the hydraulic opening and closing machine shell saves time and effort in hammer replacement and maintenance, the equipment runs smoothly, and saves more than 20% of electricity, leading the industry in terms of technology.

III. Full-cycle service guarantee

Including free on-site survey, customized process design, equipment installation and commissioning, 24-hour after-sales response, regular replacement reminders for wear-resistant parts, remote operation and maintenance monitoring, and full escort from selection to operation, so that customers have no worries.

Fill in the information and we will contact you as soon as possible