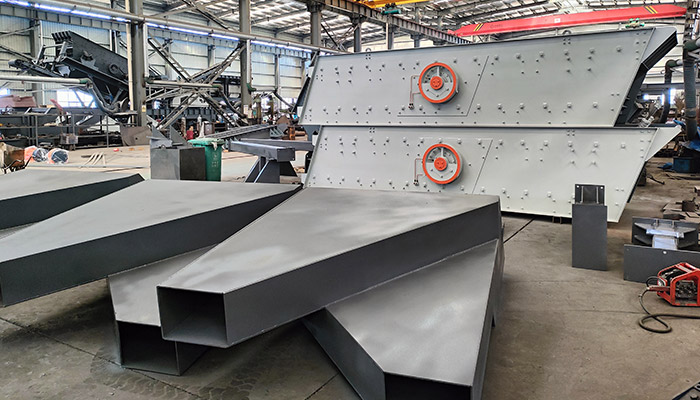

YA series vibrating screen is a multi-layer circular vibrating screen. It has a long screen line and is suitable for screening products of various specifications. Our vibrating screen uses a barrel-type eccentric shaft vibration exciter and an eccentric block to adjust the swing. It has the characteristics of reliable structure, strong excitation force, high screening efficiency, low vibration noise, durability, easy maintenance, and safe operation.

It is widely used for screening in mining, building materials, transportation, energy, chemical industry and other industries.

|

Model |

Layer of |

Size of Sieve Pore (mm) |

Max. Feeding |

Capacity |

Double Amplitude |

Motor power (kw) |

Screen Specification (mm) |

|

3YA1548 |

3 |

3~100 |

300 |

22~160 |

8 |

15 |

1500×4800 |

|

2YA1848 |

2 |

3~100 |

300 |

32~276 |

8 |

18.5 |

1800×4800 |

|

3YA1848 |

3 |

3~100 |

300 |

32~276 |

8 |

18.5 |

1800×4800 |

|

4YA1848 |

4 |

3~100 |

300 |

32~276 |

8 |

18.5 |

1800×4800 |

|

2YA1860 |

2 |

3~100 |

300 |

65~586 |

8 |

22 |

1800×6000 |

|

3YA1860 |

3 |

3~100 |

300 |

65~586 |

8 |

22 |

1800×6000 |

|

4YA1860 |

4 |

3~100 |

300 |

65~586 |

8 |

22 |

1800×6000 |

|

2YA2160 |

2 |

3~100 |

300 |

81~720 |

8 |

30 |

2100×6000 |

|

3YA2160 |

3 |

3~100 |

300 |

81~720 |

8 |

30 |

2100×6000 |

|

4YA2160 |

4 |

3~100 |

300 |

81~720 |

8 |

37 |

2100×6000 |

|

2YA2460 |

2 |

3~150 |

300 |

90~810 |

8 |

37 |

2400×6000 |

|

3YA2460 |

3 |

3~150 |

300 |

90~810 |

8 |

37 |

2400×6000 |

|

4YA2460 |

4 |

3~150 |

300 |

90~810 |

8 |

37 |

2400×6000 |

|

2YK3072 |

2 |

3~200 |

300 |

180~1300 |

8 |

30×2 |

3000×7200 |

|

3YK3072 |

2 |

3~200 |

300 |

180~1300 |

8 |

30×2 |

3000×7200 |

It uses cylinder-type eccentric shaft and eccentric block to make strong vibrating force.

Beam is connected to the main body with bolts, has the feature of high strength.

Side plate of the screen box is made of high strength and high impact resistance steel boiler plate.

It adopts small amplitude, high frequency and large obliquity structure, which enable the vibrating screen has the advantages of high screening efficiency, large processing capacity, long service life, low power consumption and low noise.

We configured a PE500X750 and PYB900 cone crusher combined mobile station for the customer. The vibrating feeder feeds the granite below 400mm into the PE500x750 jaw crusher for primary crushing, and then it to the PYB900 cone crusher for secondary crushing. The vibrating screen is used to screen out the finished building materials required by the customer.

We configured a PE500X750 and PYB900 cone crusher combined mobile station for the customer. The vibrating feeder feeds the granite below 400mm into the PE500x750 jaw crusher for primary crushing, and then it to the PYB900 cone crusher for secondary crushing. The vibrating screen is used to screen out the finished building materials required by the customer.

The customer required to produce powder below 1mm, and the output is 30-50 T/H, so we configure a fine crusher as the secondary crusher for the customer.

Fill in the information and we will contact you as soon as possible